Loading

Choice and selection of coating types

|

While the material used for the coating of a glove plays an essential role in selecting the right product, in addition to the choice of liner, the type of coating finish will also influence the basic properties and quality of the finished product : dexterity, flexibility, resistance, breathability etc.

|

|

Crinkle finish

The glove undergoes a specific treatment after coating of the material which gives it a finish in the form of wavelets and gives it a rough appearance.

Glove is often thicker.

The type of finish is used for latex.

It improves the grip and resistance of the palm.

|

|

Smooth finish (flat finish)

Uniform and smooth coating; leaves less trace on objects.

Provides good impermeability against liquids like oils & greases for nitrile coatings gloves, and against some chemicals for PVC and nitrile coatings gloves (if fully coated).

This finish is generally stiffer than a foam finish.

Good grip in dry conditions but finish which can be more slippery in wet conditions.

Less breathable than a foam coating but more resistant in particular to abrasion. |

|

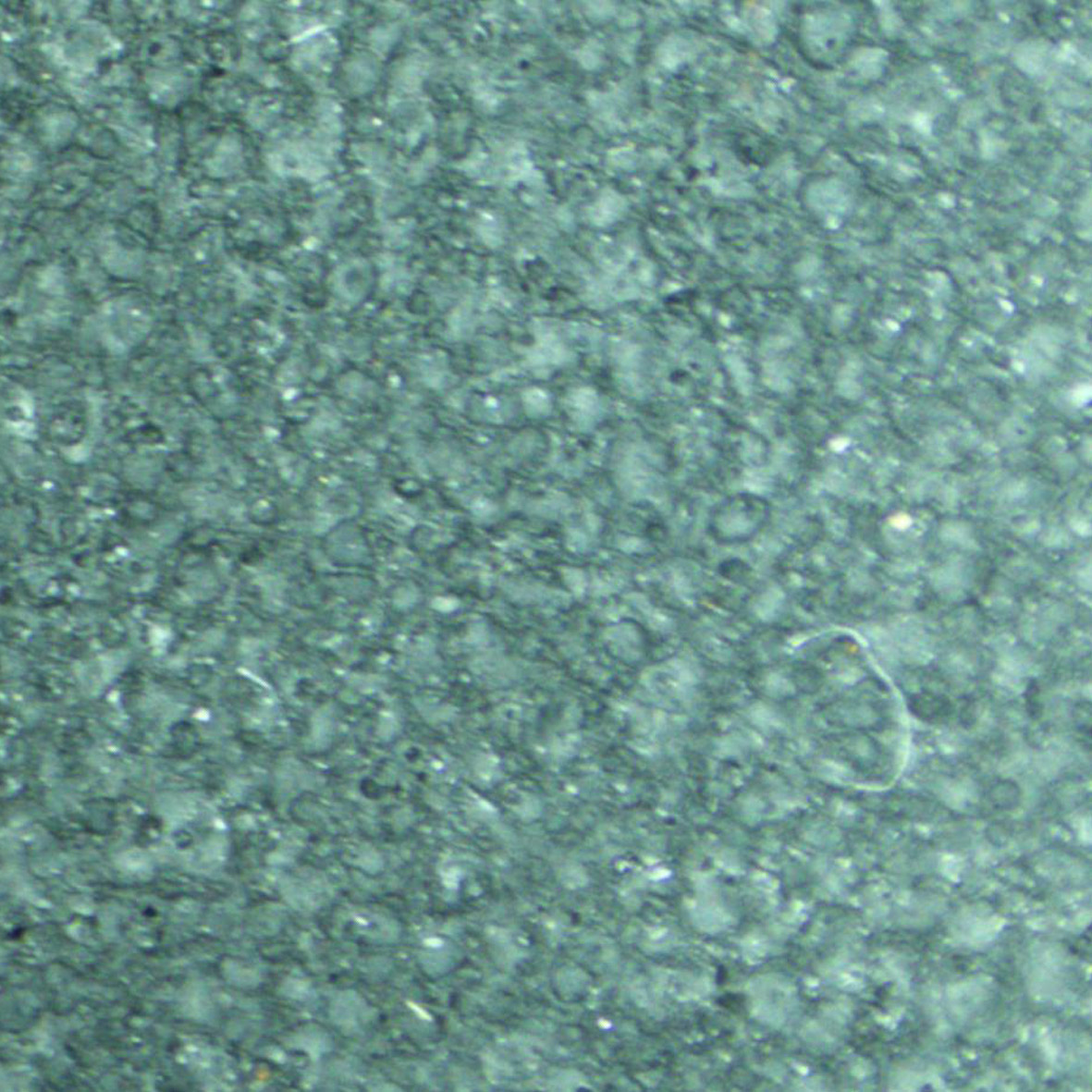

Foam finish

The honeycomb-type coating has mini air cavities giving a porous, spongy appearance.

This finish allows liquids not to stagnate on the palm, thus offering a good grip in wet conditions.

The glove is not waterproof.

Very flexible and comfortable coating, with a "second skin" effect, giving the sensation of having a glove very close to the hand (a).

More breathable than a smooth coating but less resistant especially to abrasion.

Some gloves have a double coating, smooth in the first layer for good impermeability and foam in the second layer for good grip in wet conditions; disadvantage, the glove becomes a little less flexible. |

|

Sandy finish

Finish that presents a grainy appearance, small grains, like sand.

Good flexibility and abrasion resistance.

Good grip in dry and wet conditions.

|

|

Embossed finish

Used on unsupported gloves

The coating molds (generally porcelain hands) are formed from hollow designs (diamonds, dots etc.).

After coating the molds, these designs appear on the palm of the hand in the form of a slight non-slip relief.

This finish improves the grip of unsupported gloves.

|

|

Dotted finish

On the palm we can see small dots of material.

This finish improves grip and thermal insulation.

This finish can come in addition to a coating (foam coating for example on the NYMFIT00 glove) or on gloves not previously coated (ex: TCC507)

|

|

CFT (Compressed Formula Technology) HPTTM (Hydropellent technology)

The CFT (Compressed Formula Technology) HPTTM (Hydropellent technology) coating process creates a thin layer of material that is flexible, consistent and durable.

Very good handling of manipulated objects.

|

|

-------------------------------------------------------------------------------------------------------------------------------- (a) the feeling of finesse and "second skin" also depends on the nature of the liner (type of materials, number of threads ...) and its construction (seamless machine knit, gauge ...)

Copyright Singer® Safety

Reproduction of this document is prohibited without the written consent of Singer® Safety.

This information is given for information only and does not engage the responsibility of Singer® Safety

|

Issue 2021.05.05